As a food manufacturing enterprise, Yihai Kerry has always given top priority to product quality and safety, actively fulfilled its social responsibility, and continued to provide consumers with nutritious, healthy, safe and delicious products.Yihai Kerry values the quality and safety of its products, strictly complies with the food quality and safety laws and regulations in all places of its operation, and has established a sound quality control and review system in all places of its operation to strictly control each operation process and improve quality management level.

-

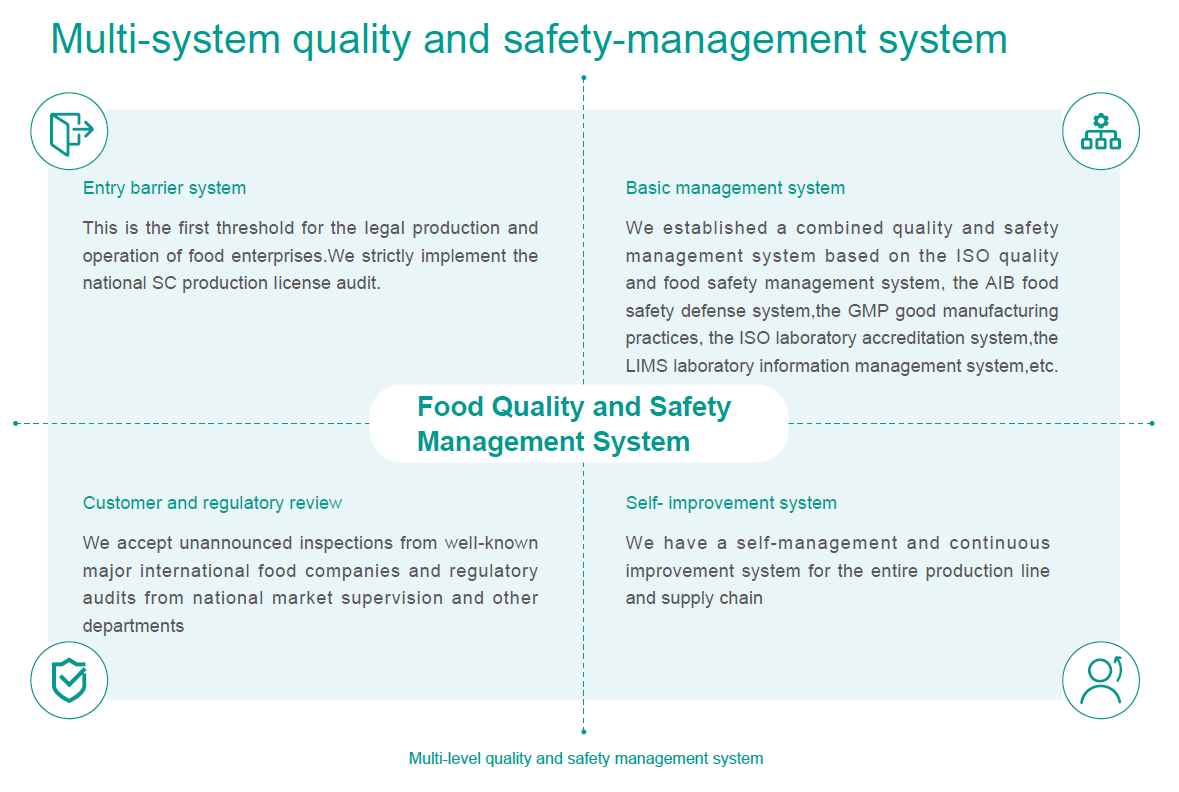

Multi-system quality and safety-management system

The Company strictly complies with the provisions of the Food Safety Law of the People's Republic of China, the Regulations for the Implementation of the Food Safety Law of the People's Republic of China, and other laws and related regulations,combined with the GB 14881 General Hygiene Practice for Food Production, the ISO 9001 Quality Management System,the ISO 22000/FSSC 22000 Food Safety Management System, the ISO 17025 Testing and Calibration Laboratory General Requirements for Proficiency, IP Certification (Non-GMO Identity Maintenance), and multiple industry chains and industry-standard requirements, such as the BRC Food Safety Standard (British Retail Consortium) and the AIB Unified Food Safety Standard (American Institute of Baking).We have implemented internal standardized management and established a risk management system covering all key points of quality and safety, focusing on excellence, and built a multisystem,multi-level, effective quality and safety management system.

The China Quality Award, established in 2012 and is selected every two years, is the highest honor in the field of quality in China. On September 16, 2021, the China Quality (Hangzhou) Conference and the 4th China Quality Award Ceremony were held in Hangzhou. With the "Four F,One New" management model of "World Quality, Healthy China", Yihai Kerry was nominated for the China Quality Award and was the only grain and oil company on the shortlist for this year's China Quality Award.

-

Quality and safety risk management for the whole industry chain

Based on the multi-system and multi-level management guarantee system, the Company has established a risk management and quality-control system covering the whole industrial chain and the whole life cycle of products, from raw and auxiliary materials,production, and marketing to customers, and strives to improve the efficiency in raw material and product tracing, quality monitoring,and food safety guarantees with the help of information management and technology to create a healthy and safe corporate culture.

Raw material risk

The Company has formulated a system for key materials,such as raw and auxi l i a ry materi a l s , processing aids, and packaging materials, and selects suppliers according to the relevant management requirements in the "Group Supplier Approval and Review" procedure.We draw a "risk map" for agricultural products, conduct upstream source research, establish and gradually improve the management method, starting from seed supervision, guide farmers to standardize planting, the use of pesticides and fertilizers, storage and delivery, and reduce the risk of non-standard operations. For other materials, we have a multi-dimensional evaluation system, based on the compliance of incoming raw materials, and access the risk-assessment results.We established a database for main suppliers, auxiliary suppliers and backup suppliers for all raw materials to reduce the risk caused by the unstable supply of individual suppliers.For more information on supplier management, please refer to the supplier management chapter of this report.

Production and storage riskThe Company has established a quality and safety management system for self-management and continuous improvement of the entire production line and supply chain. Through selfinspection,food safety team inspection, internal audits,cross-inspection, AIB unannounced audits, and a customer supervision mechanism, we constantly look for improvement opportunities, continuously optimize the guarantee system,and ensure the suitability and effectiveness of our standards.

Workshop and factory self-inspection: Each factory conducts self-inspections according to the product risk level and in accordance with the "Group Food Safety Assurance Procedures". To ensure the effectiveness and comprehensiveness of the inspection, the factory adopts the form of cross-exchange area inspection to identify problems from different angles, and track and verify the improvement results.Group audit: Based on the factory report, the Company's quality control department tracks the factory's rectification plan,summarizes the relevant key risks, and requires each factory to implement the plan item by item.

Customer audits: The Company welcomes audits by internationally renowned clients, and has achieved satisfactory audit results so far.

Audit by a third-party professional organization: The Company introduced AIB site audits. By the end of the 2021,71 factories had passed the site audits. This has greatly promoted the normalized management of food safety in various factories, strengthened the construction of the Company's quality and food safety culture, and especially improved the food safety awareness of our employees.

Market risk

To ensure product quality and build consumer confidence, we are committed to maintaining product competitiveness and effectively control shelf-life risks. We formulated the "Quality Monitoring and Management System for Market Products and Competing Products",and for new products, flavored products, and key products, we randomly check market end products and competing products every month, compare flavor and physical and chemical indicators, and optimize our products according to the strengths and weaknesses.

-

Quality Management Inspection

We pay attention to the testing and monitoring of product quality and are committed to quality control through the establishment of a comprehensive inspection system, whole-process quality control, and a system of supervisors covering a wide range of areas to strictly control product quality.

Product quality control measures Comprehensive inspection system Our laboratories in each factory are equipped with a large number of testing instruments to carry out product testing, covering basic physical and chemical indicators, quality stability indicators, nutritional indicators, characteristic indicators, mandatory food safety indicators,risk monitoring, potential hazardsindicators, etc. , fully covering all kinds of quality and safety standards for major products.

We are also equipped with a large amount of online testing equipment in the production line to improve product quality and real-time control of environmental pollution.Quality control of the whole process Combining product characteristics, processes and risk assessment, we formulated raw and auxiliary materials, and packaging material input risk monitoring, incoming inspection and production process inspection, finished product storing inspection, inventory inspection,delivery inspection, and shelf life risk monitoring systems. The inspection plan and control standards of the whole process make up the quality control of the process and ensure that product quality meets the corresponding national and industry standards. “Arawana" Quality Supervisor Program In 2008, we launched the "Arawana" quality supervisor program. Since then, we have recruited quality supervisors nationwide, and opened key factories to accept quality supervision from all levels of society to achieve "zero distance" communication with consumers, to achieve more comprehensive and rigorous supervision, and to establish and improve long-term quality supervision mechanisms. Information construction of quality management

The Company promotes the information construction of quality management to improve the efficiency of quality management, work on information sharing, enhance product traceability and early warning mechanisms, and provide a guarantee for the stability and reliability of product quality while improving production capacity and timeliness.

Quality Management Online Platform

Quality Data Management System (QDMS): Manages product standards, inspection data, quality reports,and other reports.

Document Management System (KDMS): Enables the electronic management of documents related to quality and food safety management to help the unification, sharing and traceability of documents.

Product Traceability Platform (WTP): Executes the forward and reverse efficient traceability of raw materials, intermediate products, and finished products; the introduction of blockchain technology has improved the credibility of traceability data.

Risk Early Warning (QDMS): Monitors external information. We established an external product sampling inspection and risk early warning platform, and follow up on the processing progress and results of events in a timely manner through the system. We cooperate with our food partner network to establish an information monitoring platform.

Unqualifised Review Management (SAP/EPM): Implements the management of unqualified review of purchase and incoming inspections, and effectively tracks and calculates the processing of unqualified raw materials.

In 2021, the Company did not receive any food safety violations or penalties, or product recalls due to food safety issues.

-

Product Quality and Safety Training

The Company conducts yearly trainings on product quality and safety, product nutrition and health, etc. The Company also organizes supplier conferences, visits and reviews to provide appropriate education and training to our suppliers on product quality and safety.Through a comprehensive internal and external training system, including new employee induction training, on-site training, skills practice, project training and study tours, the Company conducts multi-category training on quality and safety awareness, food safety system knowledge and standard requirements, and quality statistical analysis tools, providing comprehensive quality education at multiple levels and in all areas. The Company established a food safety training system and promoted front-line employees to participate in quality skills training. In 2021, a total of 75,786 employees had received product quality and safety trainings.

-

Industry Development

We believe that promoting the overall development of the grain, oil and food industry requires the participation of all enterprises, so we carry out in-depth cooperations with all parties in developing standards and continue to promote the healthy development of the industry.

Standardization and technical committee work

In 2021, we participated in nine standardization and technical committees, involving national food safety standards, oil and grain, storage and logistics, machinery and equipment, and feed standards, and other national standards, as well as industry standards, group standards, and other regulations at all levels.

Standard formulation

The Company has participated in the formulation and review of 50 standards, including 1 international standard, 17 national food safety standards, 11 national standards, six industry standards, five local standards, and 10 group standards.

In terms of general national food safety standards, we participated in the formulation and review of general standards in many ways,such as participating in discussions as an industry representative and providing industry data.

In terms of product standards, as a leading edible oil company, we promotes the formulation and review of standards such as GB 2716 "National Food Safety Standard Vegetable Oil" and testing methods for oil and fat characteristic indicators (polar components and acid value).

In 2021, the Group's rice, wheat flour for beef ramen, whole wheat flour, rapeseed oil (Class A), soybean oil (Class A), sunflower oil (Class A), corn oil (Class A) and sesame oil were awarded the "Standard Forerunner" of the enterprise standard for cereals and oil products announced by the State Administration of Grain and Material Reserves.